Two-dimensional Nanosheets by Liquid Metal Exfoliation

Since graphene was first successfully exfoliated, two-dimensional materials have shown broad application prospects in numerous fields such as energy storage, flexible devices, electronics, photonics, biomedicine, and catalysis. Among the methods for the scalable synthesis of two-dimensional materials, the liquid-phase exfoliation method, which weakens the van der Waals forces in bulk layered materials and disperses atomically layers in liquids, is a commonly used approach for exfoliating two-dimensional materials.

In the liquid-phase exfoliation approach, ultrasonic treatment is typically utilized to break the van der Waals forces. However, this procedure often leads to substantial variations in the thickness of the resultant dispersed two-dimensional nanosheets. Simultaneously, to obtain single-layer or few-layer two-dimensional nanosheets with high yields, strategies like ball milling, the addition of surfactants, as well as high-power and high-temperature mechanical exfoliation are frequently employed. Nonetheless, the introduction of extra energy and the addition of surfactants can give rise to contamination issues, create additional defects, and result in the obtained two-dimensional nanosheets having relatively small lateral sizes.

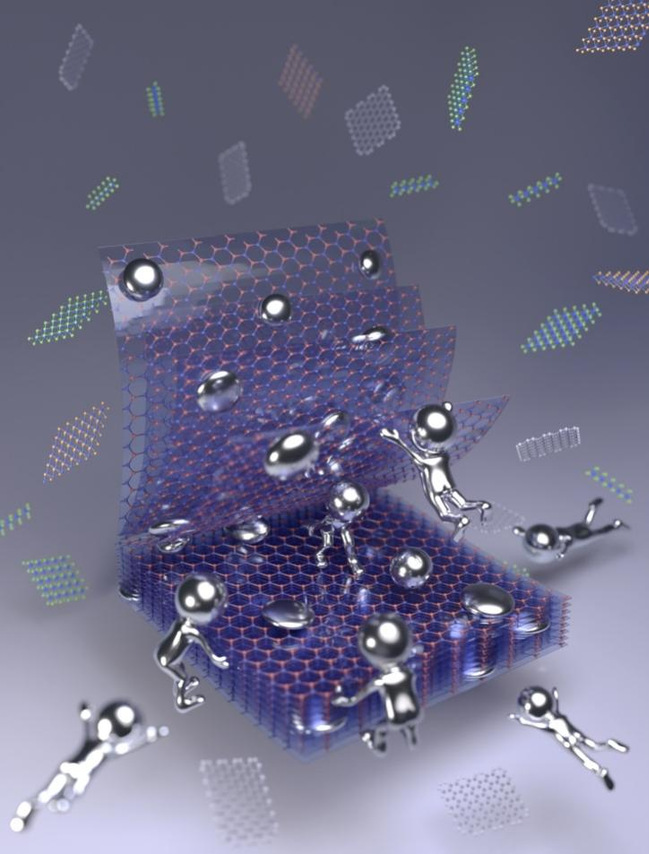

Recently, the team of Yu Lei from Tsinghua Shenzhen International Graduate School (Tsinghua SIGS), in collaboration with the team of Professor Mauricio Terrones from the Pennsylvania State University, has creatively developed a universal method for exfoliating two-dimensional materials assisted by liquid metal gallium (Ga). This method can effectively exfoliate two-dimensional materials from bulk materials without introducing additional defects. The molten Ga is gently mixed with the powder of layered materials by using a magnetic stirrer. With the intercalation effect of liquid metal between the two-dimensional layers, the interlayer spacing is expanded and the exfoliation process is triggered. Moreover, the fluid characteristics of gallium and the adhesion properties of gallium oxide (Ga₂O₃) enable the gentle shear force generated by magnetic stirring to exfoliate two-dimensional layers from the bulk crystals. This dual effect forms a universal approach that can be applied to exfoliate a variety of two-dimensional materials, including graphene, MoTe₂, MoSe₂, WSe₂, MoS₂, WS₂, NbSe₂, vermiculite and h - BN. For different applications, the crystal quality of the exfoliated two-dimensional nanosheets can be well controlled by the defect level of the bulk crystals. By using high-crystalline-quality hexagonal boron nitride, the exfoliated hexagonal boron nitride nanosheets (BNNS) exhibit a significant magneto-birefringence effect, with a Cotton-Mouton coefficient as high as 2.9×10⁶ T⁻² m⁻¹. This property makes them suitable for use as stable modulators based on the principle of birefringence. It has also been demonstrated that by introducing extended vacancies into bulk molybdenum sulfide through cryogenic ball milling, the exfoliated molybdenum sulfide nanosheets with multiple defects show a significantly enhanced catalytic activity when used as catalysts for the hydrogen evolution reaction (HER).

Liquid metal-assisted exfoliation process and universality.

The related achievements were published in the journal Advanced Materials under the title of Two-dimensional Nanosheets by Liquid Metal Exfoliation. The corresponding authors of the paper are Assistant Professor Yu Lei from Tsinghua SIGS and Professor Mauricio Terrones from the Pennsylvania State University. The first author is Yichao Bai, a doctoral student enrolled in 2023 at Tsinghua SIGS. The co-authors include Professor Feiyu Kang, Professor Bilu Liu, and Assistant Professor Hongzhang Wang from Tsinghua SIGS, Professor Humberto Terrones from Rensselaer Polytechnic Institute in the United States, and Assistant Professor George Bepete from Concordia University in Canada, among others.

V-MoS₂ for detecting monoamine neurotransmitters in the Gut-Brain Axis

Furthermore, in the field of biological applications of two-dimensional materials, this team has also developed an electrochemical sensor based on single-atom V-doped MoS₂ (V-MoS₂). The single-atom catalytic sites (SACs) of V in V-MoS₂ can bind with small monoamine molecules more effectively, enabling highly selective real-time detection of serotonin (5-HT) in artificial gastric/intestinal fluid. The synergistic effect between the V-SACs and the S bonds on the surface of MoS₂ results in an extremely wide detection range for 5-HT (ranging from 1 pM to 100 μM), along with excellent selectivity and anti-interference properties. Combined with the results obtained from density functional theory calculations and scanning transmission electron microscopy, it can be concluded that the V-SAC active sites embedded in MoS₂ significantly facilitate the charge exchange between the material and 5-HT molecules. This result provides a more powerful tool for the detection of 5-HT in the research on the Gut-Brain Axis (GBA). Moreover, leveraging the tunability of defect-engineered materials offers a universal platform for the real-time and multi-component detection of other monoamine neurotransmitters (such as dopamine and norepinephrine) in the GBA.

This research work was published in the journal Small under the title of Vanadium Single Atoms Embedded in MoS2 Enabled Gut-Brain Axis Neurotransmitter Detection at pM Levels. The corresponding authors of the paper are Professor Feiyu Kang, Assistant Professor Yu Lei from Tsinghua SIGS, and Professor Mauricio Terrones from the Pennsylvania State University. The first author is Linxuan Sun, a doctoral student enrolled in 2024 at Tsinghua SIGS. This research was supported by the National Natural Science Foundation of China, the Ministry of Science and Technology, the Department of Science and Technology of Guangdong Province, and the Shenzhen Science and Technology Innovation Commission.

Link to full article:

https://doi.org/10.1002/adma.202416375

https://doi.org/10.1002/smll.202307410

Written/Images by Bai Yichao, Sun Linxuan

Edited by Yuan Yang

Reviewed by Chen Chaoqun